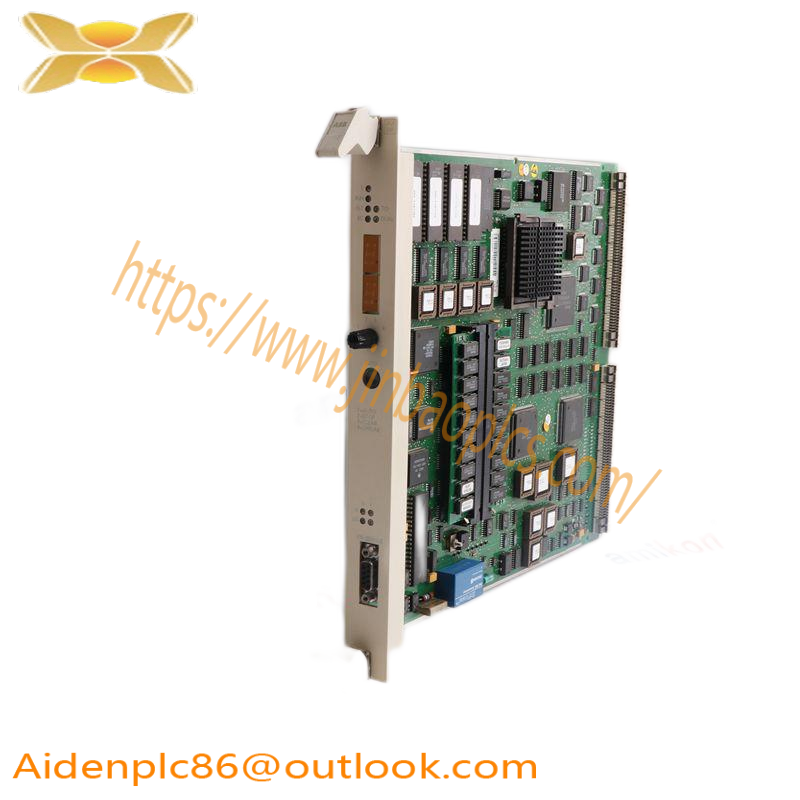

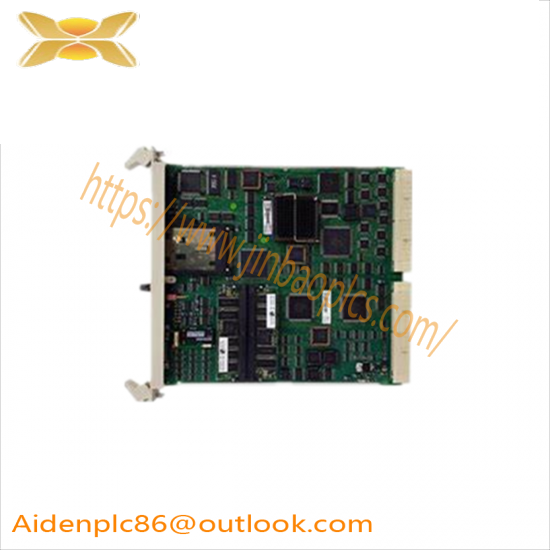

XVC770AE 3BHE006414R0001 is a key processor unit module (Processor Unit Module) in ABB’s industrial automation system and a core component of the ABB 800xA system (or its predecessor, the Advant Master system). It is responsible for executing control logic, processing data, coordinating communications, and ensuring high reliability and real-time performance of the system. The following is a detailed analysis from the dimensions of technical specifications, functional features, application scenarios, maintenance optimization, etc.

Core hardware specifications

1. Processor performance

Architecture: Based on the ARM Cortex-R series or PowerPC architecture (depending on the version), it has hard real-time processing capabilities.

Main frequency: 200-400 MHz, meeting high-speed control requirements (such as motor speed regulation, valve fast closing).

Memory:

Flash: 2-4 MB, storing firmware, control logic and historical data.

RAM: 512 KB-2 MB, supporting multi-task parallel processing (such as running PID control and communication protocol stack at the same time).

2. Interface and scalability

Communication interface:

Dual Ethernet ports: support 10/100 Mbps rate, can be configured as redundant links (such as HRP protocol) to ensure zero network interruption.

Serial interface: 1×RS485 (optional RS232), used to connect field instruments or third-party devices (such as Modbus RTU devices).

Fieldbus interface: supports PROFIBUS-DP, Foundation Fieldbus (FF), HART and other protocols, and directly integrates intelligent sensors/actuators.

I/O expansion:

Connect ABB’s CI (Controller Interface) series I/O modules through the backplane bus, supporting analog (AI/AO), digital (DI/DO), pulse (PI) and other signals.

Maximum expansion capacity: 128 I/O channels (depending on system configuration).

3. Redundancy Design

Hardware Redundancy:

Hot Standby Redundancy: The main and standby processor modules run synchronously and automatically switch when a fault occurs (switching time <50 ms).

Power Redundancy: Supports dual power input (24V DC), and single power failure does not affect operation.

Software Fault Tolerance:

Watchdog Timer: Monitors task execution status and automatically resets when timeout.

Data Verification: Perform CRC verification on key parameters (such as set values and feedback values) to prevent data damage.

Core Functional Features

1. Control Logic Execution

Programming Language: Supports ABB standard Control Builder M tool, using IEC 61131-3 standard languages such as Function Block Diagram (FBD), Ladder Diagram (LD), Structured Text (ST) for programming.

Control Strategy:

Continuous Control: PID regulation, ratio control, cascade control, etc.

Sequential control: Supports SFC (sequential function chart) programming for batch processing and equipment start and stop logic.

Safety control: Optional SIL2/SIL3 certified versions to achieve safety functions such as emergency shutdown (ESD) and fire and gas detection (F&G).

2. Communication and data exchange

System communication:

Interact with other modules (such as I/O, HMI, engineer station) through the AC 800M controller of ABB System 800xA or the MasterBus 300 bus of Advant Master system.

Supports OPC UA protocol to achieve data integration with third-party systems (such as SCADA, MES).

Field communication:

As a Modbus TCP/RTU master station, collect field equipment data (such as flowmeters, pressure transmitters).

As a PROFIBUS-DP slave station, receive control instructions from PLC or DCS.

3. Diagnosis and maintenance

Self-diagnosis function:

Real-time monitoring of processor temperature, voltage, and communication status, and alarms through LED indicators or system logs.

Supports predictive maintenance with ABB System 800xA’s Asset Optimization tool.

Firmware upgrade:

Upgrade firmware online through Control Builder M or ABB 800xA Configuration Studio to fix vulnerabilities and improve performance.

Typical application scenarios

1. Power industry

Generator control:

Monitor turbine speed, boiler pressure, and grid frequency, and adjust steam valve opening through PID control.

Achieve automatic generation control (AGC) and respond to grid dispatch instructions.

Substation automation:

Process circuit breaker position, protection device signals, and perform remote control/remote adjustment operations.

Communicate with intelligent electronic devices (IEDs) through IEC 61850 protocol.

2. Petrochemical and Chemical Industry

Reactor Control:

Adjust temperature, pressure, and pH value to ensure safe and efficient chemical reactions.

Link Emergency Shut-off Valve (ESDV) to prevent overpressure or leakage.

Pipeline Monitoring:

Collect flow and pressure data, and trigger alarm or interlocking action through logical judgment.

3. Metallurgical Industry

Blast Furnace Control:

Optimize wind temperature, wind pressure, and material speed to reduce coke ratio and improve molten iron quality.

Blast furnace forward control is achieved through expert system.

Continuous Casting Machine Control:

Synchronize the pulling speed, crystallizer vibration, and secondary cooling water volume to prevent cracks in the ingot.

4. Water Treatment and Environmental Protection

Wastewater Treatment Plant:

Control aeration fans and dosing pumps to achieve water quality discharge standards.

Remotely monitor the parameters of each process section through the SCADA system.

Desalination:

Adjust the parameters of the multi-effect evaporator (such as temperature and vacuum) to improve the water production efficiency.

Summary

The XVC770AE 3BHE006414R0001 processor unit module is the “core engine” of ABB’s industrial automation solutions. Its high reliability, multi-protocol compatibility and redundant design make it the first choice for critical infrastructure. Users need to select the appropriate version according to actual needs and establish a standardized maintenance process (such as regular firmware upgrades and environmental monitoring) to maximize the life of the equipment.

Related product recommendations:

ABB PP885 3BSE069276R1

ABB 3HNA024871-001

ABB ACU-01B 3HNA024871-001

ABB 3BHE017628R0002

ABB 3BHE017628R0002 PPD115A02

ABB 3BHE017628R0002 PPD115A02

ABB LS4000

ABB PFTL101B 2.0KN 3BSE004185R1

ABB 3BSE004185R1

ABB 3BSX802939-108

ABB PFCL201CE 50KN 3BSX802939-108

ABB PPC907BE 3BHE024577R0101

ABB 3BHE024577R0101

ABB 1TGE120021R0010

ABB PM865K01 3BSE031151R1

ABB 3BSE031151R1

More…

There are no reviews yet.