Boeing CEO grilled about salary, accountability in second day of congressional questioning

Key Points

In a heated exchange, Rep. Steve Cohen asks Boeing CEO Dennis Muilenburg whether he is taking responsibility for the fallout from the 737 Max crashes.

Cohen asks if Muilenburg or anyone else at the company will be taking a pay cut because of 737 Max issues. Muilenburg says the board will make those decisions.

Boeing replaced the head of its commercial airplane unit Kevin McAllister earlier this month. He is the senior-most executive to leave in the wake of the catastrophes.

Boeing CEO Dennis Muilenburg was grilled about his salary on Wednesday, the second day of congressional hearings about the company’s 737 Max jets, which were involved in two fatal crashes.

Rep. Steve Cohen, D-Tenn., questioned in a heated exchange whether Muilenburg was taking responsibility for the fallout from the crashes, which killed 346 people in total. Cohen asked if anyone at the company had taken a pay cut amid the grounding of the 737 Max.

“You’re saying you’re not giving up any compensation at all,” Cohen asked Muilenburg. “You’re continuing to work and make $30 million a year after this horrific two accidents that caused all these people’s relatives to go, to disappear, to die.”

Muilenburg earned total compensation of just under $23.4 million for 2018, according to a Securities and Exchange Commission filing. He also cashed in delayed stock payouts from previous years, bringing his total actual compensation for the year to $30 million.

Boeing is not handing out executive bonuses this year, according to a company spokesperson.

When Muilenburg was asked directly if he would take a cut in pay, he said the company’s board makes those decisions.

“You’re not accountable then,” Cohen said. “You’re saying the board’s accountable.”

Boeing replaced the head of its commercial airplane unit Kevin McAllister earlier this month. He is the senior-most executive to leave in the wake of the catastrophes.

Muilenburg said during the questioning Wednesday by members of the House Committee on Transportation and Infrastructure that he has not offered to resign following the 737 Max crashes.

Rep. Peter DeFazio, D-Ore., who chairs the committee, also challenged Muilenburg on his compensation and the consequences he has faced after the two crashes.

“You are the CEO of the largest aircraft manufacturer in the world,” DeFazio said. “You’re earning a heck of a lot of money, and so far the consequence to you has been, oh, you’re not chairman of the board anymore.”

Muilenburg appeared before the Senate Commerce Committee on Tuesday.

Here is the full exchange between Cohen and Muilenburg:

Cohen: Is anybody at Boeing taking a cut or working for free to try to rectify this problem? Like the Japanese would do?

Muilenburg: Congressman, my board will conduct a comprehensive review …

Cohen: So you’re saying you’re not giving up any compensation at all? You’re continuing to work and make $30 million a year after this horrific two accidents that caused all these people’s relatives to go, to disappear, to die. You’re not taking a cut in pay at all?

Muilenburg: Again, our board will make those determinations.

Cohen: You’re not accountable then. You’re saying the board’s accountable.

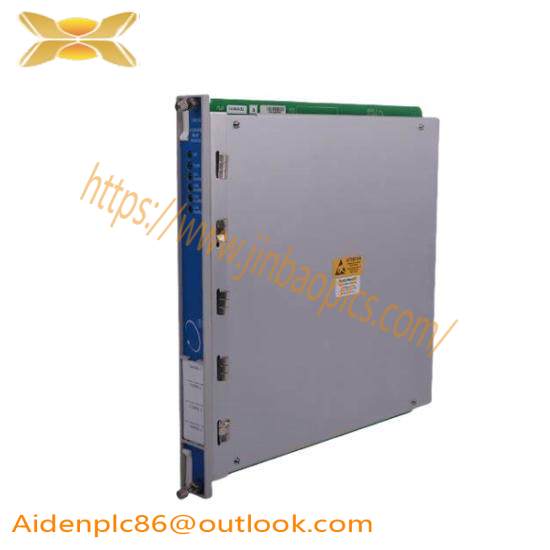

Related product recommendations:

ABB 3BHB005243R0105

ABB NTAC-02 58967441E

ABB DO810 3BSE008510R1

ABB UAC389 HIEE410506P104

ABB 1SVR630180R3300

ABB CT-APS.22

ABB 1SVR630180R3300

ABB UFC921A 3BHE024856P201

ABB KUC755AE105 3BHB005243R0105

ABB TU830V1 3BSE013234R1

ABB 3BSE013175R1

ABB LT2005-S/SP19

ABB GRBTU-01 3BSE013175R1

more……